Categorías

Nuevo blog

Comparison between laser welding machine and laser cutting machine

Mar 20, 2024

There are several types of laser marking machines, laser welding machines, laser cutting machines, etc., because the names are somewhat similar, sometimes it is easy to make some mistakes. Often some friends cannot distinguish between laser welding machines and laser cutting machines, so laser welding what are the differences between laser welding machines and laser cutting machines? Next, PES Laser technicians will briefly explain to you the differences between laser welding machines and laser cutting machines:

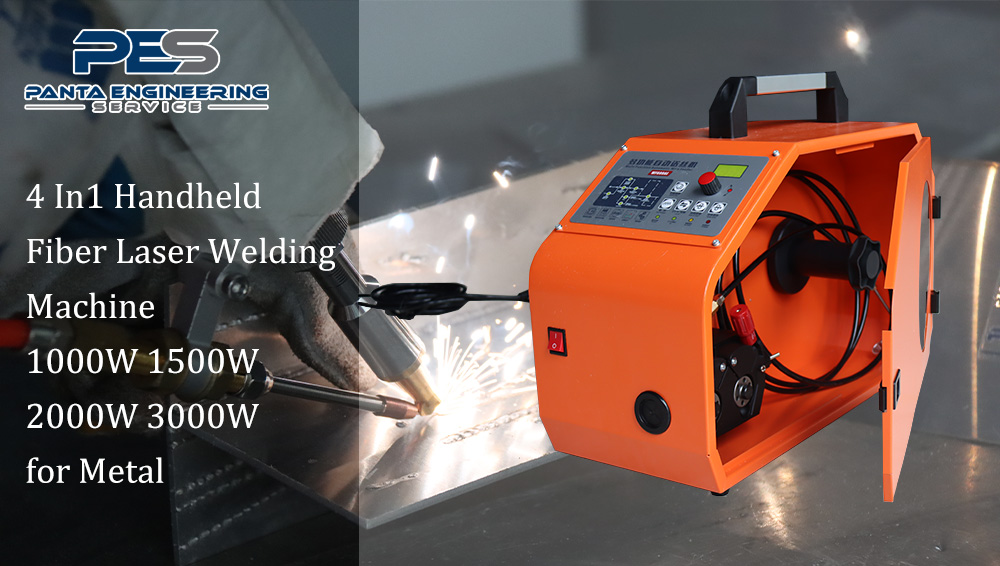

1. Fiber laser welding machine:

Laser welding machine is a new type of welding method. It is mainly used for welding thin-walled materials and precision parts. It can realize spot welding, butt welding, stack welding and sealing welding. It has a high depth ratio, small weld width and heat-affected zone. Small, small deformation, fast welding speed; large welds are smooth and beautiful, no processing is required or only simple processing procedures are required after welding; the welds are of high quality, no pores, the structure can be refined after welding, and the strength and toughness of the welds are at least equivalent to that of the parent material Made of metal; it can be precisely controlled, the focused light spot is small, it can be positioned with high precision, and it is easy to realize automation. Laser welding uses high-energy pulse laser to achieve welding. The laser power supply first lights the pulse xenon lamp, and pulses discharges the xenon lamp through the laser power supply to form a light wave with a certain frequency and a certain pulse width. The light wave radiates to the Nd³:YAG laser crystal through the focusing cavity, stimulating the Nd³:YAG laser crystal to emit light. After resonating in the laser resonator, a pulse laser with a wavelength of 1064nm is emitted. The pulse laser is focused on the object to be welded after beam expansion, reflection, (or optical fiber transmission); it is completed under the control of a PLC or industrial PC. welding.

2. Laser cutting machine:

The laser cutting machine is equipped with a low-pressure coaxial air blowing system and convenient air nozzle replacement; high cutting accuracy, fast speed, strong optical transmission stability, high-speed cutting without saw teeth, and high production efficiency; equipped with a waste funnel for easy collection and cleaning of waste materials; optional Equipped with a cutting head follower module, it is suitable for cutting plates that are not very flat or have a large processing range. Laser cutting is achieved by applying high power density energy generated by laser focusing. Under the control of the computer, the laser is discharged through pulses, thereby outputting a controlled repetitive high-frequency pulse laser, forming a beam of a certain frequency and a certain pulse width. The pulse laser beam is transmitted and reflected through the optical path and focused on the focusing lens group. On the surface of the processed object, tiny, high-energy-density light spots are formed. The diameter of the light spot is generally 0.01~0.4mm. The focal spot is located near the surface to be processed, and the material to be processed is melted or vaporized at high temperature in an instant.

3. The difference between laser welding machine and laser cutting machine:

Laser welding machines are used to weld metal, and laser cutting machines are used to cut metal. Although it is difficult to determine the specific difference in internal parameters between the two from the definition and indirection of the two, according to experience, the two can actually achieve symbiosis on the same machine, but the programming process is slightly Different, the laser power called is different.

¿Como podemos ayudarte?