Nondestructive testing technology of detection methods after laser cleaning

Oct 31, 2024Laser cleaning is a technology that uses high-energy laser beams to irradiate the surface of the workpiece, causing the coating, dirt or rust on the surface to be instantly removed or peeled off, thereby achieving cleanliness. It has the advantages of environmental protection, wide contact-free application range, and high cleaning accuracy. It has good cleaning effects in paint removal, rust removal and cultural relics restoration. It is widely used in many fields such as aerospace, shipbuilding, rail transportation, automobile manufacturing, precision instruments, and cultural relics.

The laser power density of laser cleaning has a cleaning threshold and a damage threshold. Only when it reaches above the cleaning threshold will the cleaning effect be produced and it cannot exceed the damage threshold. Otherwise, it will cause damage to the substrate, resulting in the destruction of the surface integrity of the substrate, the decline of surface performance, and thus the failure to meet the use requirements. Therefore, the substrate after laser cleaning should be subjected to nondestructive testing.

Nondestructive testing methods refer to methods for evaluating the internal functional realization and structural performance indicators of the structure without destroying the external structural integrity of the detection object. The use of nondestructive testing methods can locate and analyze the substrate morphology, defect location and type, location information, etc., and predict the service life based on the defect situation, material and other conditions, which can further reduce costs under the condition of production safety. This article mainly introduces several commonly used laser cleaning nondestructive testing methods: penetration testing, magnetic particle testing, ultrasonic testing, radiographic testing and eddy current testing.

1. Penetration testing

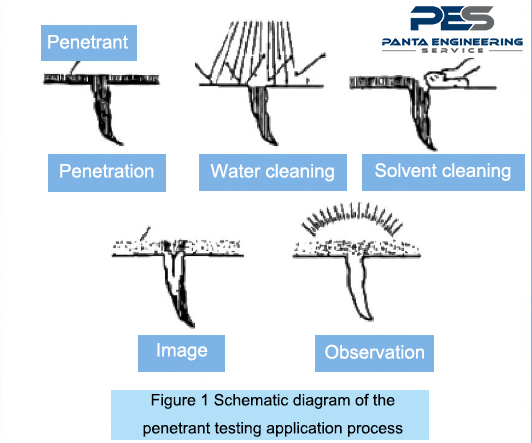

Penetration testing is a method of checking surface defects of materials using capillary phenomena. The application process is shown in the figure below. Apply penetrant to the surface of the structure to be tested, and penetrate into the tiny defects of the surface opening under the action of capillary tubes. Use a cleaning agent to remove the penetrant, wait for a period of time for the test piece to reach a dry state, apply a developer, and absorb the residual penetrant. Observe the defective part and you can clearly see the traces of the penetrant. According to the traces, the location and shape of the defect can be clearly determined.

2. Magnetic particle testing

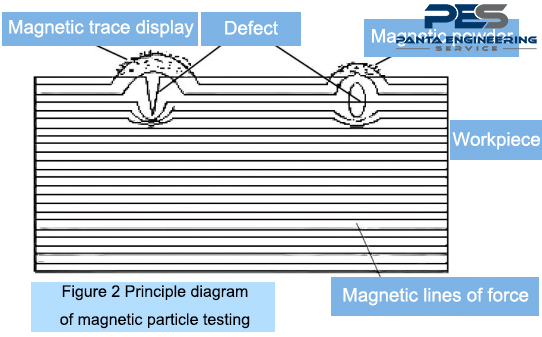

Magnetic particle testing is a method for detecting surface and near-surface defects of ferromagnetic materials. When the workpiece is magnetized, if there are defects on the surface or near the surface of the workpiece, leakage magnetic flux is generated due to the increase in magnetic resistance at the defect, forming a local magnetic field, and the magnetic powder will show the shape and location of the defect here. Magnetic particle testing has the advantages of low cost, low pollution, high sensitivity, and convenient operation, but it lacks feasibility in the detection of internal defects of components and the judgment of the depth of surface defects, and can only detect ferromagnetic materials, as shown in the figure.

3. Ultrasonic testing

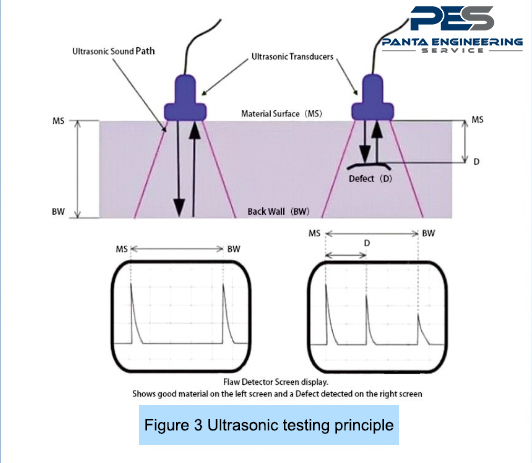

Ultrasonic testing is a method of inspecting defects in parts by using the characteristics of ultrasonic energy penetrating deep into metal materials and reflecting at the edge of the interface when entering another section from one section. The probe sends ultrasonic pulses to the part being tested. During the propagation, it encounters defects with different acoustic impedances. Part of the ultrasonic wave that reaches the defect interface or the bottom of the part is reflected. After receiving the pulse waveform, the probe analyzes the amplitude and phase information of the pulse waveform to clarify the location and size of the defect, and can make a judgment on the specific situation of the defect in the weld, as shown in the figure.

Ultrasonic testing has the ability to identify and locate internal defects in welds. It has low cost, high accuracy, and good safety performance. It has a good application effect in the detection of area defects; but the detected pulse waveform results are not intuitive, and the detection results generated by different defect positions are different in accuracy, such as poor detection results on the surface or near the surface of the part. When the structure being tested is irregular, it is also difficult to achieve good detection results.

4. Radiographic testing

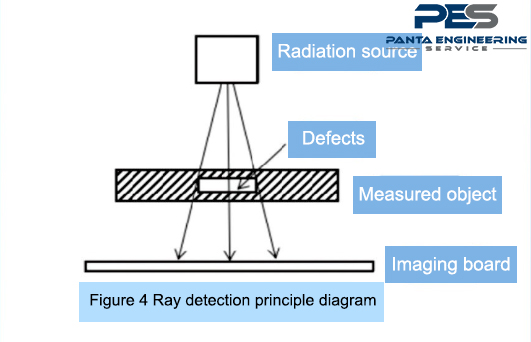

Radiographic testing is a method of detecting defects by using X-rays or other radioactive sources to penetrate the inspected object with different attenuation intensities, so that the film is sensitive to different blackness. If the defective part has a stronger ability to absorb radiation than other parts, the intensity of the radiation at the defective position will be weakened. By observing the processed film, internal defects can be clearly found and the position and shape of the defects can be determined, as shown in the figure.

X-ray detection intuitively presents the internal quality status of the component in the form of a projected image, generates a detection structure with long-term preservation conditions, and determines defects in a qualitative and quantitative manner. It has a good effect in detecting internal volume defects such as pores. However, it lacks feasibility in the detection of cracks or other area defects, which is mainly related to the radiation irradiation angle. For example, if the radiation irradiation direction is parallel to the defect direction, the defect detection rate is low. In addition, the detection work has certain limitations such as danger, slow detection speed, high detection cost, and susceptibility to external interference. Therefore, this detection method is less used.

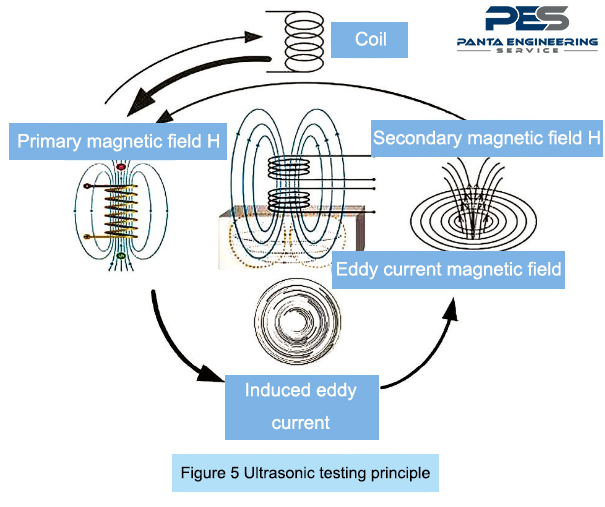

5. Eddy current detection

Eddy current detection does not require coupling agent. It is easy to realize high-speed and high-efficiency automatic detection of tubes, rods, and wires. It has high sensitivity, simple operation, and relatively comprehensive information extraction. However, it is only suitable for detecting conductive metal materials or non-metallic materials that can induce eddy currents; secondly, due to the influence of the skin effect, it can usually only detect surface or near-surface defects of the workpiece.

¿Como podemos ayudarte?