Laser welding of materials

Aug 02, 2024PES LASER's handheld fiber laser welding machine, equipped with the fourth-generation swing welding gun, greatly improves the strength and quality of the welded joint and obtains better weld formability. The handheld laser welding machine can perform spot welding, straight seam welding, lap welding, girth welding and arbitrary orbital welding. The machine is also equipped with an automatic wire feeder. Compared with traditional argon arc welding, the efficiency is increased by more than 50%.

Replacing the old-fashioned thermal welding system with a handheld welding gun not only facilitates the welding of molds, advertising words, kitchen utensils, doors and windows, etc., but also makes laser welding possible in outdoor operations. The welding capacity is expanded from small and lightweight workpieces to large and bulky objects that are difficult to move, such as stainless steel silos, stainless steel spiral ducts, chimney pipes, automobile steel pipe feeders, etc., with almost no size restrictions, indicating that traditional welding such as electric welding and argon arc welding will inevitably be replaced by laser welding.

With the development of science and technology, traditional welding methods can no longer meet the special requirements of many industrial technologies for materials. Laser welding is the use of high-energy laser pulses to locally heat a material in a small area. The energy of laser radiation is mainly diffused to the internal information of the material through the study of heat conduction, and the material is melted to form a specific molten pool to achieve the purpose of improving welding. It is easy to operate and can weld a wider range of materials.

At present, the types of materials suitable for laser welding are extremely wide, from conventional ferrous metals (such as carbon steel, alloy steel, stainless steel, etc.) to non-ferrous metals (such as aluminum alloys, magnesium alloys, copper alloys, titanium alloys, etc.), including some plastics, glass and ceramics. Laser welding (or connection) can weld the same material, and can also weld certain combinations of dissimilar materials. The laser weldability of different materials is explained below.

1. Carbon steel

Generally speaking, carbon steel, especially low carbon steel, has excellent laser weldability. When the carbon equivalent of carbon steel is greater than 0.3%, the weld will have a higher hardness, but the tendency of cold cracking will increase. These two points will cause brittle fracture under fatigue and low temperature conditions. The following methods can be used to improve the situation:

(1) When designing the joint, allow a certain amount of deformation (which can reduce the stress at the joint and HAZ) to reduce the tendency to crack

(2) When welding materials with a carbon equivalent greater than 0.30% and materials with a carbon equivalent much less than 0.30%, using a welding bias can also reduce cracking (because it helps to reduce the carbon equivalent level at the joint interface, thereby limiting the martensitic transformation)

(3) Reduce the cooling rate, and use preheating/post-heat treatment, dual beams (large spot for preheating/post-heating, small spot for welding or energy distribution 3:7), and low power and low speed welding to ensure a certain penetration depth

Fully killed steel or semi-killed steel (i.e., steel with a reduced dissolved oxygen content by adding oxidizing elements such as aluminum and silicon before steel injection) can be used for laser welding. If the steel is bare steel, laser welding is not recommended unless the oxygen content is reduced to an acceptable range by other means, otherwise porosity defects are likely to occur.

Steels with S and P contents greater than 0.04% have poor laser weldability and are prone to thermal cracking, which is caused by low-melting-point brittle sulfides or phosphides. When welding free-cutting steels or ingots containing sulfur, phosphorus, selenium, cadmium or lead (usually cumulative content does not exceed 0.05%), welding pores or solidification cracks may occur.

Carbonized steels are generally not suitable for laser welding because of their high surface carbon content, which will produce welding solidification cracks and shrinkage cracks in the carbide layer. Laser melting welding of nitrided steel is also not recommended because it will reduce the surface hardness near the weld, and the welds produced will have pores and may also crack.

Galvanized steel sheets have a low boiling point of zinc in the interlayer (about 903℃, far lower than the melting point of steel 1535℃). During welding, high-pressure zinc vapor is easily generated in the interlayer, causing unstable molten pool and even large particles to splash, resulting in weld pores and undercuts. If the thickness of the zinc coating in the interlayer is less than 5-10μm, a good weld may also be obtained. However, a 10-20 μm zinc coating is usually required to achieve adequate corrosion protection. If the galvanized sheet and bare sheet are welded at the lap joint, a good weld can be obtained. Compared with hot-dip galvanized steel, electro-galvanized steel is more suitable for laser welding because its coating thickness is more uniform.

The following methods can be used to solve the problem of zinc vaporization at the lap joint:

(1) Design an exhaust path by introducing a small, controllable gap at the lap joint, or by providing a zinc vapor exhaust path through the weld design. These methods include: adding process gaskets, embossing, punching dimple to create cavities, designing the weld into a Y-shaped or edge joint, and designing the fixture to form a gap near the welding part. Generally, the exhaust channel gap is equivalent to the total thickness of the coating to minimize pores and not cause welding defects.

(2) Control the exhaust time and vaporization temperature or pressure. Generally, pulse welding or zero defocus is used to reduce the volume of vaporized zinc to reduce pores and unfused steel plate zinc hot-dip welding.

2. Stainless steel

(1) Austenitic stainless steels have good laser weldability, but some austenitic stainless steels (such as 300 series 303, 303 Se, stabilized 321 and 347) may have a tendency to hot cracking due to the addition of sulfur and selenium to improve machinability. Due to the lower thermal conductivity (about 1/3 of carbon steel) and slightly higher absorption rate, austenitic stainless steels can achieve slightly deeper weld depths (about 5-10%) compared to ordinary carbon steel. Due to the relatively low heat input and fast welding speed, 300 series stainless steels are very suitable for laser welding, and the corrosion resistance of the weld metal will not deteriorate due to high heat input. In addition, compared with traditional welding techniques, the thermal deformation and residual stress of austenitic stainless steels are smaller in laser welding, especially their thermal expansion coefficient is 50% higher than that of ordinary carbon steel. Austenitic stainless steels have good laser weldability when the Cr equivalent/Ni equivalent is greater than about 1.6. If the Cr equivalent/Ni equivalent is lower than this value, the tendency to hot cracking becomes higher. Cr/Ni can be approximately calculated using the following relationship:

Cr equivalent ≅ Cr + Mo + 0.7Nb + 3Ti

Ni equivalent ≅ Ni + 35C + 20N

(2) Ferritic and martensitic stainless steels Compared with other welding processes, laser welding of 400 series (ferritic stainless steel) generally has higher ductility and plasticity. However, due to the formation of martensite and grain coarsening caused by fusion welding, the strength and corrosion resistance of the weld will be reduced. Compared with austenitic and martensitic stainless steels, laser welding of ferritic stainless steel generally has the lowest tendency to hot and cold cracking. The martensitic series has the worst laser weldability among stainless steels, and the weld is very hard and brittle, with a tendency to cold cracking. For grades with a carbon content higher than 0.1%, preheating and tempering can be used to reduce cracking and embrittlement.

3. Special alloys

Titanium and titanium alloys can also be laser welded, but titanium is easily oxidized and easily forms gap embrittlement with oxygen, hydrogen, nitrogen and carbon in the environment or materials, so special attention must be paid to the surface cleanliness of the parent material and inert gas protection. Magnesium and magnesium alloys generally have HAZ cracks and holes when laser welding. Cobalt and cobalt-based alloys have good weldability, but some high-alloy forms may have cracks in the fusion zone and HAZ.

4. High temperature and weather-resistant materials

Most nickel-based alloys have good laser welding performance, such as 718, Hastelloy X and Inconel 600. Refractory metals (such as niobium, tantalum, molybdenum and tungsten) and their alloys can also be laser welded (although tungsten alloys may crack). Similar to titanium, refractory alloys are also sensitive to gap embrittlement, so special attention must be paid to the cleanliness of the joint and gas protection.

5. Brass, copper and aluminum alloys

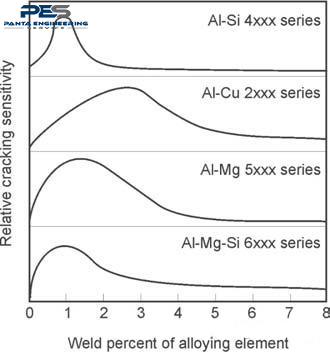

Due to the zinc content, brass has poor weldability and there is no significant improvement using different types of lasers. Zinc has a low melting point and is easily vaporized, resulting in weld porosity and poor fusion. Copper alloys have a high reflectivity to CO2 laser wavelengths, but this is greatly reduced at the wavelength of solid-state lasers. Therefore, YAG lasers, fiber lasers, and disk lasers are generally used to weld copper alloys, especially green lasers and blue lasers, to achieve lower power and greater penetration. Similar to copper alloys, aluminum alloys are not suitable for CO2 lasers, but YAG lasers, fiber lasers, and disk lasers are relatively mature processes, and single-mode or multi-mode lasers have a wide range of application cases. 1050, 3003, and 6061 alloys have good weldability and can be laser welded. 5052 and 5082 aluminum alloys can be welded by continuous laser welding. Aluminum alloys are usually fully tested for crack sensitivity.

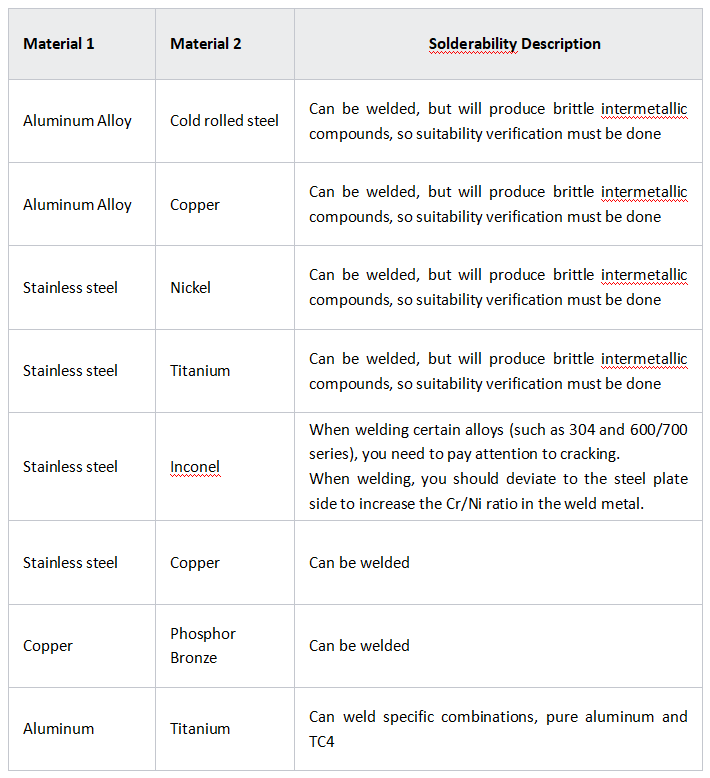

6. Dissimilar materials

When considering laser welding of two different materials, evaluating the metallographic structure of the weld is an important step, because many ideal dissimilar material combinations will form intermetallic compound areas in the weld that will cause embrittlement. A brittle weld is weaker than the two materials being welded. Therefore, it is critical to test the suitability of dissimilar materials for welding. When evaluating whether a material combination can be used for a specific application, it is important to minimize the heat input and laser action time.

Welding different alloys within the same metal family should also be considered dissimilar metal welding, such as stainless steel and aluminum alloys.

Different grades of 3XX series stainless steel are generally easier to weld, but 303 and 316 are two grades that need attention. 303 is a free-cutting steel with poor weldability due to its sulfur content, which is prone to cracks and holes. However, it can be welded with 304L alloy as long as the weld has a high 304L mixture ratio. Using a continuous laser instead of a pulsed laser can also alleviate this problem because the continuous wave laser reduces the thermal cycling of the part. For 316, the chromium-nickel ratio of the weld material must be greater than 1.7 to ensure a reliable crack-free weld. Similarly, using a continuous laser can help weld 316. Due to the high carbon content and other alloying elements that stabilize ferrite, the 4XX series does not weld well, and can be welded with 3XX series steel to improve weldability.

Welding between different aluminum alloys also belongs to dissimilar metal welding, because these aluminum alloys are quite different, and the paint must ensure that the percentage of alloying elements in the weld will not promote cracking. In electronic packaging, 6061 alloy and 4047 are often used for seam welding, because the silicon content in 4047 will bring the overall alloy percentage into a safe range of 7-8%.

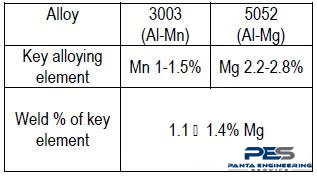

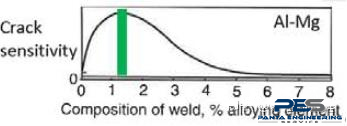

When two different aluminum alloys that are inherently weldable are connected, it is necessary to understand the final weld alloy composition. For example, when two weldable alloys such as 3003 and 5052 are welded, they are prone to cracking.

The effect of coating on laser welding:

High flat mirror coating is difficult to weld: mirror chrome plating, silver plating, silver plating, etc.

General coating is easier to weld: nickel plating, zinc plating, copper plating has no effect on welding strength.

Highly polished metals are more difficult to weld: copper, silver, gold have lower welding strength.

Other treatments are easy to weld: as long as it is not a mirror surface, the welding strength is higher.

The effect of gap on laser welding:

The smaller the gap, the better the appearance and the greater the strength. When the gap is large, a more serious groove weld will appear and the strength will also be low.

The effect of material thickness on laser welding:

For materials below 0.2, welding is difficult, the weld seam will deform, and the welding firmness will decrease. Thicker materials have better welding appearance and greater strength.

¿Como podemos ayudarte?