1. El diseño de encimera todo en uno es fácil de operar

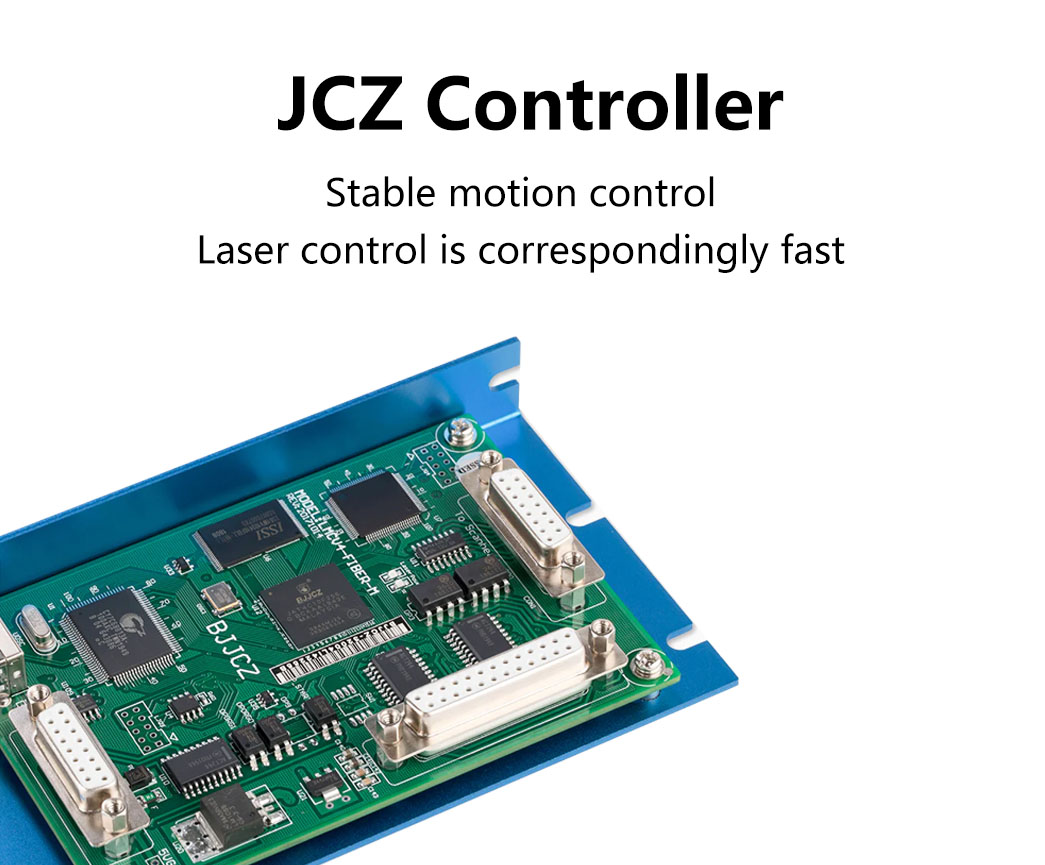

2. Sistema de control de movimiento láser de marcado de alta velocidad incorporado

3. El rayo láser de fibra tiene buena calidad, alta confiabilidad y precisión.

4. Marcado rápido en metales y ciertos materiales no metálicos (como ciertos plásticos duros)

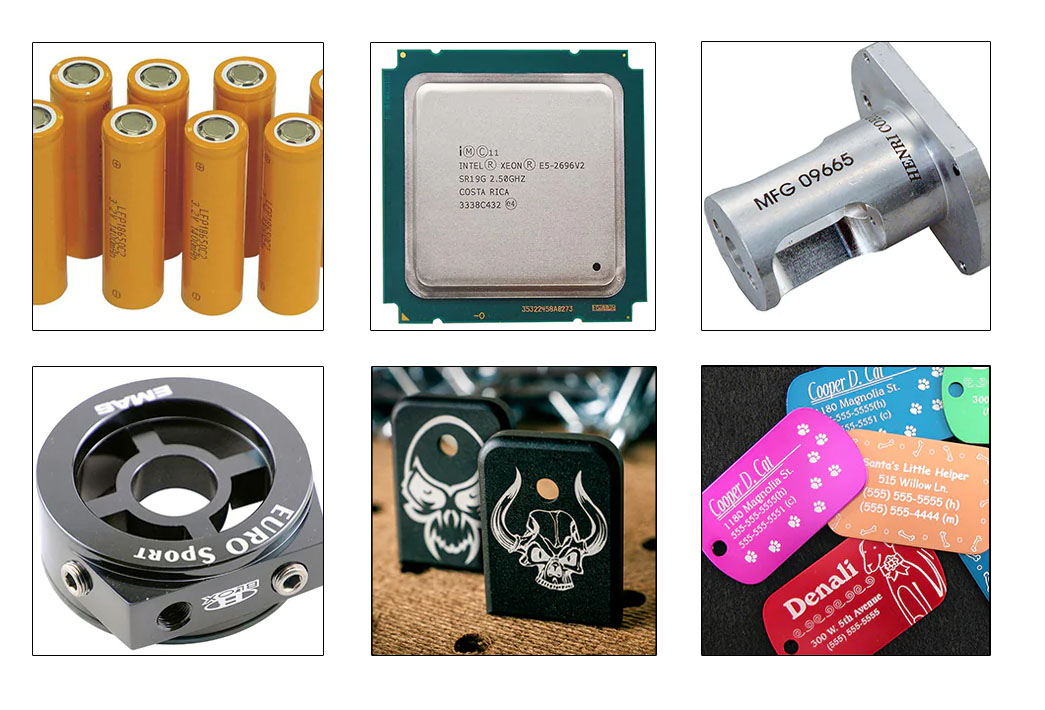

SOLICITUD

- Varios metales aplicables, como plata, aleación, aluminio, acero inoxidable, cobre, etc.

- algunos materiales no metálicos, como PVC, PC, acrílico negro.

-

Industria aplicable:

ampliamente solicitada para electrónica, joyería, automóviles, productos de comunicación, botones de plástico, IC, etc.

Red IPv6 admitida

Red IPv6 admitida